Prototyping physical-digital hybrids with cardboard and code lets you quickly turn ideas into interactive models using low-cost, sustainable materials. You can combine sturdy cardboard structures with embedded electronics and sensors, driven by microcontrollers like Arduino or Raspberry Pi. This approach supports rapid testing and iteration, blending craftsmanship with digital interactivity. If you want to explore effective design techniques, integration tips, and real-world examples, keep exploring—there’s a lot to discover.

Key Takeaways

- Combining cardboard with code enables rapid, cost-effective prototyping of interactive physical-digital hybrid models.

- Strategic placement of sensors and actuators in cardboard structures facilitates seamless digital integration.

- Proper planning of cuts, folds, and embedded electronics enhances structural stability and functionality.

- Using lightweight, durable materials and waterproof enclosures ensures longevity of cardboard-based prototypes.

- Calibration and secure wiring of electronic components are essential for reliable interactivity and user experience.

The Advantages of Combining Cardboard and Code in Prototyping

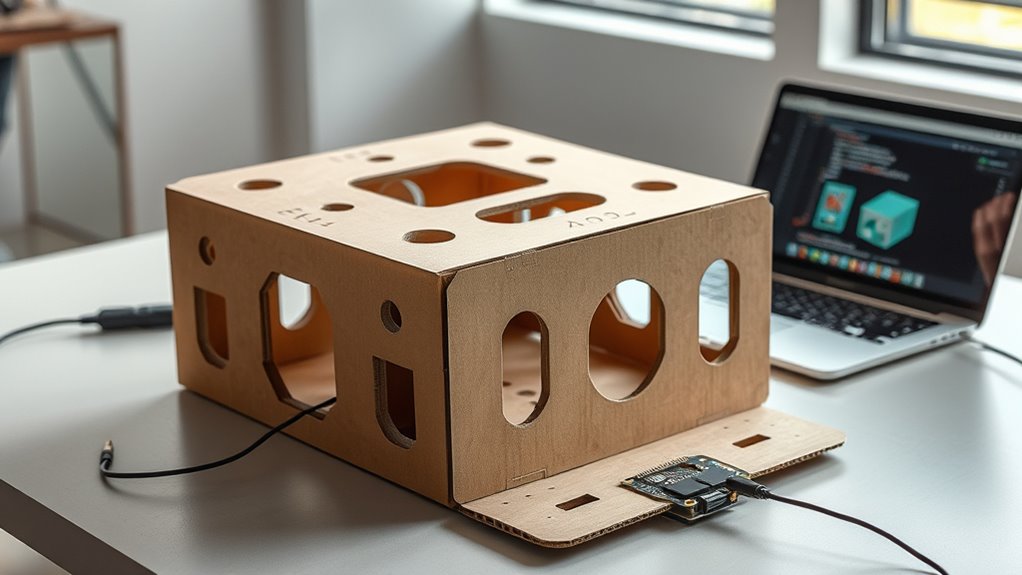

Combining cardboard and code in prototyping offers a practical way to quickly test ideas and iterate designs. This approach leverages digital fabrication techniques, allowing you to cut, shape, and assemble cardboard with precision. Using sustainable materials like recycled cardboard not only reduces environmental impact but also keeps costs low. Incorporating rustic decor elements into your physical models can help better visualize a farmhouse bedroom design, making your prototypes more relevant and inspiring. Integrating code with physical models enables you to add interactive elements, sensors, and automation, making your prototypes more dynamic. This synergy accelerates development, as you can rapidly modify both the digital and physical aspects without significant delays. Overall, this method empowers you to explore ideas efficiently, test functionality, and refine your concepts before investing in more complex or permanent solutions.

Essential Tools and Materials for Physical-Digital Hybrid Projects

To create successful physical-digital hybrids, you need the right core hardware components like microcontrollers, sensors, and actuators. Alongside these, creative craft supplies such as cardboard, glue, and paint help bring your ideas to life. Having a well-stocked toolkit guarantees you can prototype efficiently and explore innovative designs. Ensuring proper filtration and pump protection during paint application can also improve the quality and durability of your project finishes.

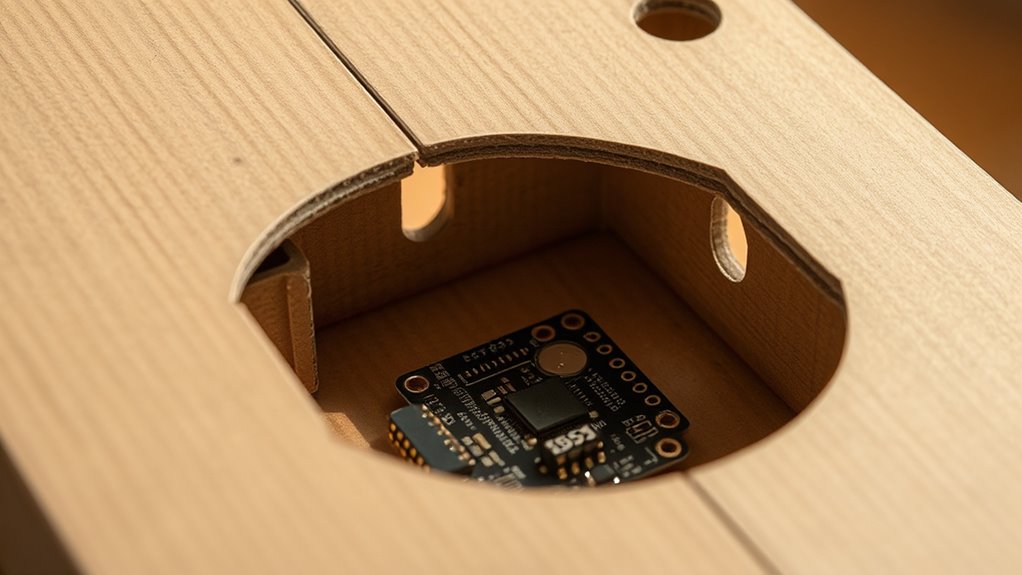

Core Hardware Components

Creating effective physical-digital hybrid projects requires a solid understanding of the core hardware components involved. Your material selection is vital; choose sturdy, lightweight materials like cardboard, acrylic, or 3D-printed plastics to guarantee structural integrity. Sensors, microcontrollers, and actuators form the backbone of your digital interface, enabling interaction between the physical and digital worlds. Microcontrollers such as Arduino or Raspberry Pi are popular choices for their versatility and ease of use. When selecting hardware, consider compatibility, power requirements, and size constraints to maintain durability and functionality. Proper integration of these components ensures your prototype is not only functional but also resilient. Trustworthiness of Patchology Focusing on reliable hardware setup lays a strong foundation for your project’s success, making it easier to troubleshoot and iterate.

Creative Craft Supplies

Having the right craft supplies is essential for bringing your physical-digital hybrid projects to life. Sustainable materials like recycled cardboard, biodegradable plastics, or eco-friendly fabrics help you create environmentally conscious prototypes. These materials are versatile and easy to work with, making them perfect for rapid prototyping and adjustments. Artistic embellishments such as paint, stickers, and textured elements add personality and visual interest to your projects. Using sustainable supplies not only aligns with eco-conscious goals but also encourages innovative thinking about material choices. Keep a variety of adhesives, cutting tools, and markers handy to refine your designs. With the right supplies, you can seamlessly blend digital components with handcrafted elements, resulting in engaging, polished prototypes that showcase both creativity and functionality. Incorporating animated movies that touch hearts can inspire emotionally engaging design elements and storytelling techniques in your prototypes.

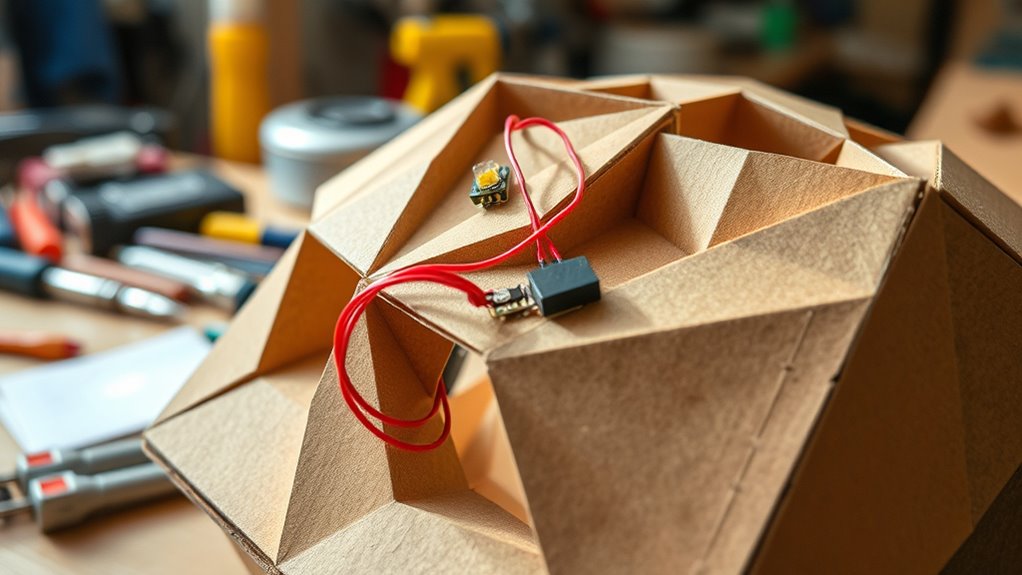

Designing Your Cardboard Structure for Functional Integration

When designing your cardboard structure for functional integration, focus on guaranteeing that each component serves a specific purpose while maintaining stability. Use sustainable materials to reduce environmental impact and promote eco-friendly prototyping. Consider ergonomic factors to guarantee your design is user-friendly and comfortable to interact with. Plan your cuts and folds carefully to maximize strength without adding unnecessary weight, which helps maintain stability. Think about how components will connect and support digital elements, ensuring access points and mounting surfaces are clear. Keep the overall form simple yet effective, avoiding overly complex shapes that could weaken the structure. By balancing sustainability, ergonomics, and structural integrity, you create a functional, adaptable prototype ready for digital integration. Incorporating self watering plant pots into your design can serve as a practical example of integrating sustainable, functional elements into your prototype.

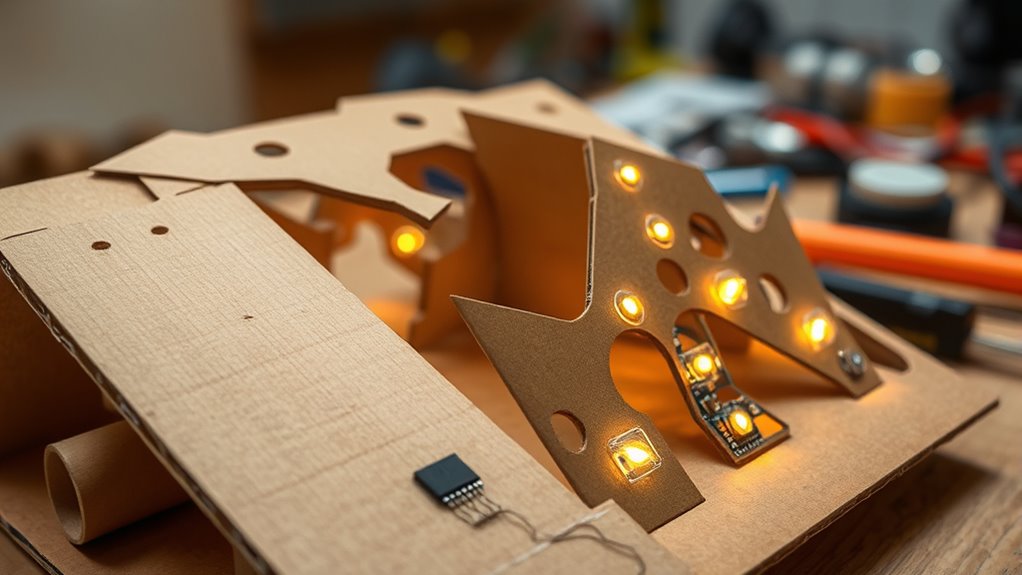

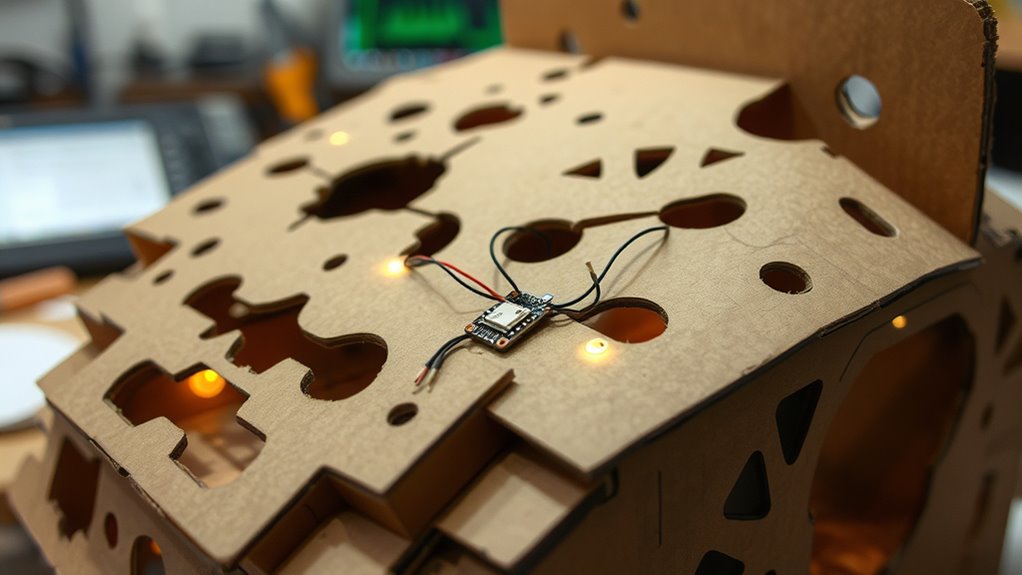

Embedding Electronics Into Cardboard Constructs

Embedding electronics into cardboard requires careful planning to ensure sensors fit seamlessly without damaging the structure. You also need to consider how to power your electronics reliably while maintaining overall durability. Addressing finishing touches helps protect your build and keeps it functional over time. Incorporating ergonomic considerations during design can further enhance the usability and longevity of your hybrid construct.

Integrating Sensors Seamlessly

Integrating sensors seamlessly into cardboard constructs requires careful planning to guarantee electronics blend naturally with the material’s form. Start by designing sensor placements that complement the structure’s shape and purpose. Proper sensor calibration is essential; it ensures data accuracy and reliable readings. Once calibrated, you can focus on data visualization, which helps interpret sensor outputs effectively. Embedding sensors involves choosing flexible, lightweight components that won’t compromise the cardboard’s integrity. Secure wires carefully to prevent movement or damage during handling. Consider using adhesive or embedded channels to hide wiring and electronics, maintaining a clean aesthetic. This thoughtful integration ensures your hybrid prototype functions smoothly while preserving a polished look, making it easier to analyze sensor data and demonstrate the project’s interactive capabilities confidently. Additionally, understanding Kia Tuning options can inspire creative modifications for hybrid prototypes, blending automotive-inspired performance enhancements with innovative design.

Powering Cardboard Electronics

Powering your cardboard electronics involves selecting compact, lightweight power sources that won’t compromise the structure’s integrity. Consider using biodegradable materials for batteries and power modules to align with eco-friendly goals and promote sustainability. Small, flexible power options like thin coin cells or supercapacitors are ideal for maintaining the design’s form while providing reliable energy. Embedding these power sources allows you to enhance your project’s visual storytelling, making the experience more engaging without sacrificing the cardboard’s natural aesthetic. By choosing eco-conscious components, you support environmentally responsible prototyping. Properly integrating power supplies ensures your hybrid remains lightweight and functional, enabling you to focus on the interaction and narrative you want to convey through your creation. Additionally, understanding the power management of embedded electronics can help optimize battery life and overall performance.

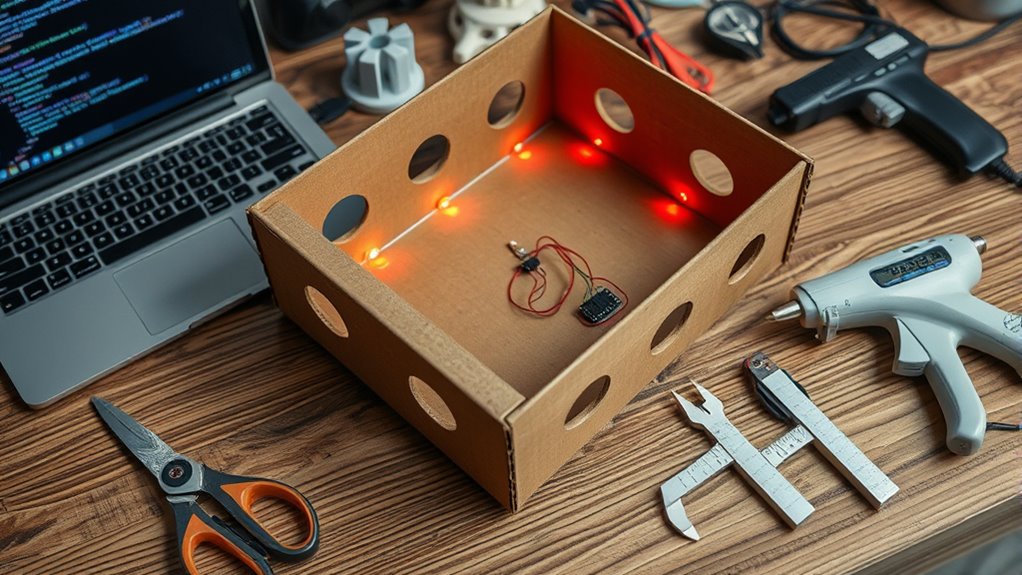

Finishing and Durability

To guarantee your electronics withstand handling and environmental factors, carefully finish and reinforce your cardboard constructs. Start with surface finishing to smooth edges and seal surfaces, reducing damage risk. Applying paint, varnish, or specialized coatings can provide a protective layer that enhances durability. Weatherproofing is essential for outdoor or moisture-prone settings; use waterproof sealants or clear coats to prevent water ingress that could damage electronics. Reinforce vulnerable areas, such as corners or joints, with tape or additional cardboard layers. Consider embedding electronics within sealed compartments or using waterproof enclosures for added protection. These finishing steps not only prolong the life of your prototype but also ensure reliable function, even in challenging conditions. Proper surface finishing and weatherproofing are key to creating resilient, long-lasting hybrid prototypes, especially when integrating smart technology into your designs.

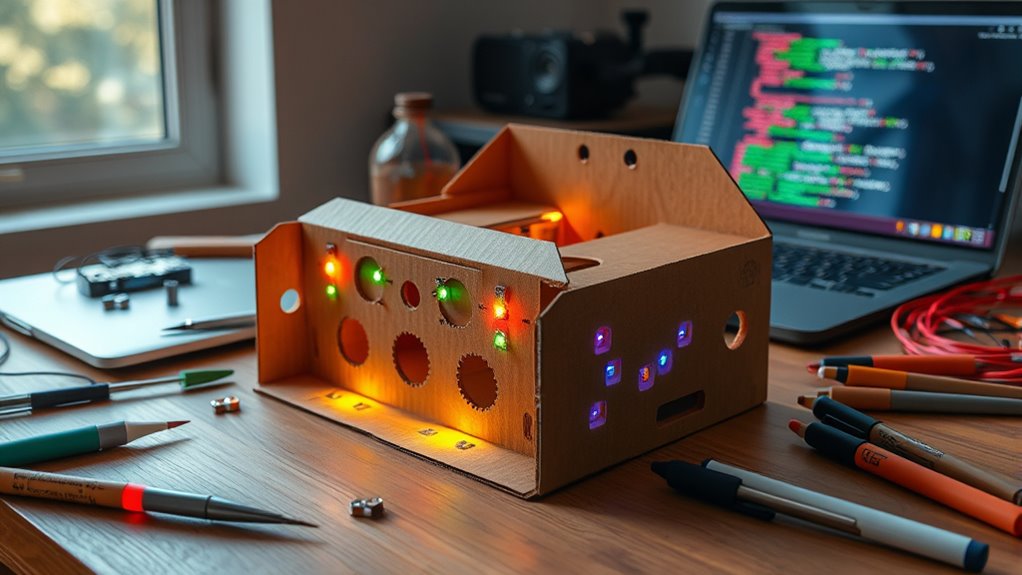

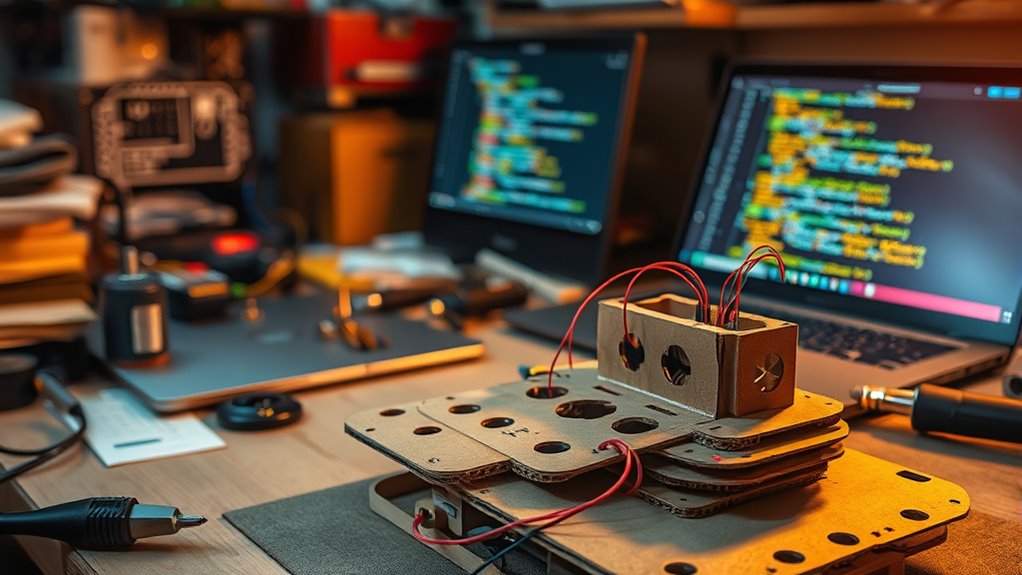

Programming Interactivity: Bringing Code to Physical Models

Bringing code to physical models transforms static prototypes into interactive experiences. By programming, you enable users to engage with your cardboard models through augmented reality or tactile feedback. Augmented reality overlays digital information onto physical objects, creating immersive, layered interactions that deepen user understanding. Tactile feedback, on the other hand, adds physical responses—like vibrations or button presses—that make interactions feel more real. To achieve this, you can use microcontrollers such as Arduino or Raspberry Pi, connecting sensors and actuators to your cardboard. Writing concise code allows you to control these components seamlessly, turning your simple model into a dynamic, responsive system. This integration makes prototypes not just visual or tactile but truly interactive, bridging the gap between physical and digital worlds.

Techniques for Connecting Sensors and Actuators to Cardboard Prototypes

Connecting sensors and actuators to cardboard prototypes requires careful planning and precise techniques to guarantee reliable interaction. To ensure accurate readings, you’ll need to perform sensor calibration, adjusting sensitivity and thresholds for top-notch performance. Using simple connectors like jumper wires, conductive tape, or screw terminals can make connections more secure and easier to modify. When attaching sensors and actuators, consider insulation and placement to prevent shorts and interference. Proper wiring reduces noise, which improves user experience by providing consistent feedback. Additionally, documenting connection points helps troubleshoot issues later. Always test your setup thoroughly, verifying sensor responses and actuator responses before integrating into the larger prototype. These techniques help create a seamless, responsive interaction that feels intuitive and engaging to users. Understanding Gold IRA rollovers can also provide insights into diversifying assets, which can be an interesting consideration for long-term planning of your projects.

Case Studies: Successful Physical-Digital Hybrid Projects

Real-world projects showcase how effective integration of sensors and actuators with cardboard prototypes can lead to compelling physical-digital experiences. For example, some designers use sustainable materials like recycled cardboard to create eco-friendly prototypes that highlight environmental responsibility. In one case, a museum exhibit incorporated sensors to trigger digital animations, enhancing visitor engagement while maintaining aesthetic customization through painted or textured surfaces. Another project involved customizing cardboard structures with printed graphics and interactive elements, blending craftsmanship with digital interactivity. These successful examples demonstrate that combining sustainable materials with thoughtful aesthetic choices not only reduces environmental impact but also elevates the user experience. By leveraging these case studies, you can see how physical-digital hybrids become innovative tools for education, entertainment, and design exploration.

Challenges and Solutions in Building Cardboard-Based Digital Prototypes

Creating cardboard-based digital prototypes presents several challenges that designers must navigate to achieve functional and durable results. Material sustainability is a key concern, as cardboard needs to withstand repeated use without excessive waste. Reinforcing structures or selecting thicker, high-quality materials can improve durability, but may impact sustainability goals. Aesthetic customization also poses difficulties; cardboard’s natural look limits design flexibility. To overcome this, you can incorporate surface treatments, paints, or printed graphics to enhance visual appeal. Balancing sustainability with durability and aesthetics requires careful material choice and thoughtful design adjustments. Addressing these challenges early ensures your prototype remains functional, visually engaging, and environmentally considerate, ultimately supporting a successful hybrid prototype that reflects both form and function.

Tips for Rapid Iteration and Testing in Hybrid Prototyping

To accelerate your hybrid prototyping process, focus on establishing a rapid iteration cycle that combines quick fabrication with immediate testing. Start by selecting materials that are easy to modify and rework, like cardboard or foam, to speed up changes. Prioritize materials that support swift adjustments without sacrificing durability or functionality. Test your prototypes early and often, gathering user feedback to refine the user experience. Keep your digital components flexible, using modular code and adaptable interfaces for quick updates. Document each iteration clearly, noting what worked and what didn’t, so you can build on successes. This approach helps you identify issues early, saving time and resources, and ensures your hybrid prototype evolves effectively to meet user needs.

Future Trends in Physical-Digital Hybrid Design

Advancements in rapid prototyping techniques are paving the way for innovative physical-digital hybrids that are more adaptable and responsive. You’ll see biomimicry inspiration increasingly influence design, mimicking nature’s efficiency and resilience to create smarter, more sustainable prototypes. Future trends emphasize sustainability considerations, prompting you to choose eco-friendly materials and energy-efficient processes. As digital fabrication becomes more accessible, you can experiment with complex geometries and responsive features that adapt in real-time. Expect hybrid designs to integrate sensory feedback for enhanced interactivity, making prototypes more intuitive. These innovations will allow you to develop solutions that are not only functional but also environmentally conscious, aligning with global sustainability goals. Ultimately, the future of hybrid design lies in combining biomimicry, sustainability, and cutting-edge fabrication to push creative boundaries.

Frequently Asked Questions

How Durable Are Cardboard-Based Digital Prototypes Over Time?

You might wonder how durable cardboard-based digital prototypes are over time. Cardboard can experience material degradation when exposed to moisture, light, or rough handling, which affects its structural integrity. While suitable for quick iterations and demonstrations, it’s not ideal for long-term use. To maintain durability, avoid water and excessive stress, and consider reinforcement or protective coatings, ensuring your prototype stays intact longer despite natural wear and tear.

What Are the Best Practices for Ensuring Safety With Embedded Electronics?

You should prioritize user safety by implementing proper electrical shielding to prevent accidental shocks or short circuits. Use insulated wiring, secure all electronic components, and avoid exposed connections. Test your prototype thoroughly for electrical safety, and incorporate clear labels or warnings if necessary. Regularly inspect your hybrid to guarantee safety measures remain effective. These practices help protect users and maintain the integrity of your digital-physical prototype.

Can These Hybrid Prototypes Be Scaled for Mass Production?

You can scale hybrid prototypes for mass production, but you’ll face scalability challenges like maintaining quality and consistency. To succeed, streamline your manufacturing process, select suitable materials, and optimize your design for automation. Address potential issues early, such as electronics integration and assembly, to ensure your product can manage large-scale production efficiently. Planning ahead helps you overcome these challenges and move smoothly from prototypes to mass-market readiness.

How Do You Troubleshoot Connectivity Issues Between Sensors and Code?

When troubleshooting connectivity issues between sensors and code, start by checking sensor calibration to guarantee accurate data. Verify wireless communication settings, like Wi-Fi or Bluetooth, to confirm proper pairing and signal strength. Test the sensors individually to identify if the problem persists, then review your code for correct data handling. Adjust calibration and communication parameters as needed, and always keep your firmware and libraries up to date for reliable performance.

What Are Cost-Effective Alternatives to Traditional Electronics Components?

Did you know that many DIY projects cut costs by up to 50%? When exploring alternatives to traditional electronics, you can consider using alternative materials like conductive fabric, recycled components, or simple microcontrollers like the ESP8266. Conducting a thorough cost analysis helps you identify budget-friendly options without sacrificing functionality. These alternatives make prototyping more accessible, especially for educational or experimental projects where keeping costs low is essential.

Conclusion

So, next time you’re tempted to spend thousands on sleek prototypes, remember: cardboard and code can do wonders—and maybe even turn heads at your next pitch. Who knew that a little tape, some wires, and a sprinkle of creativity could outshine that shiny, expensive model? Embrace the chaos, test relentlessly, and watch your digital dreams take shape—because sometimes, the best innovations come from the most humble materials. Cardboard, after all, is the future.